ABOUT iCAMM.

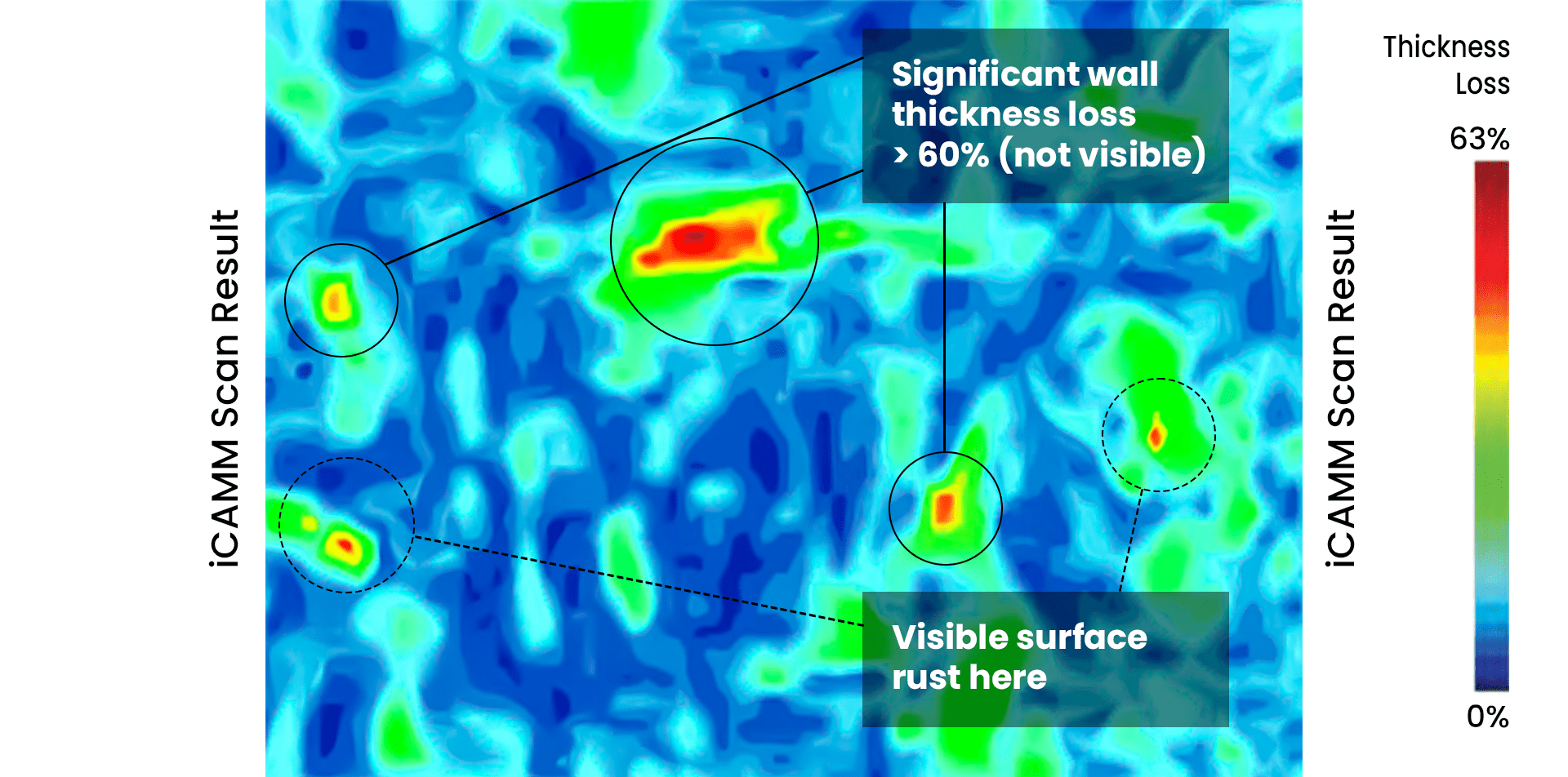

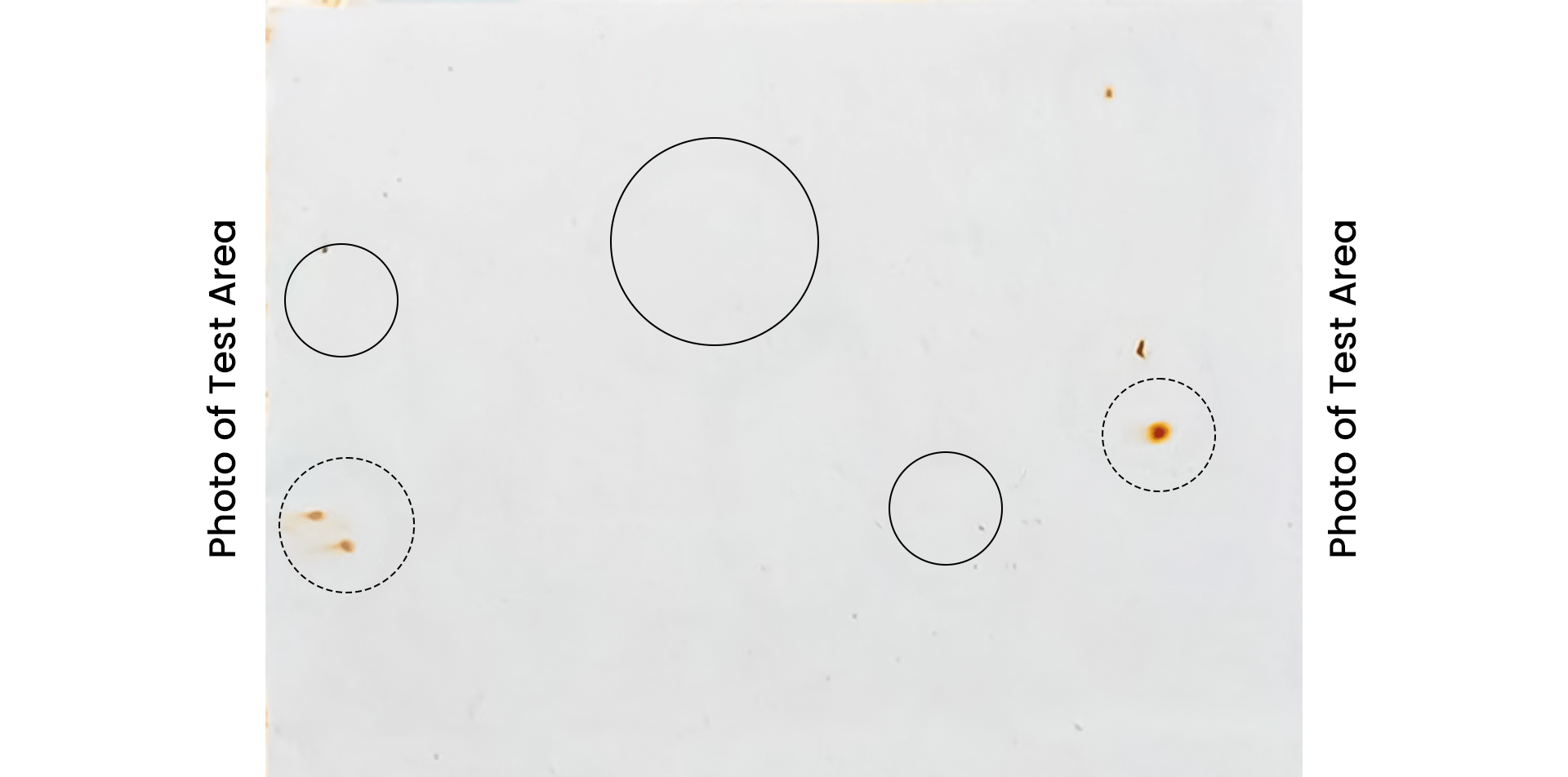

The patented ICAMM inspection system significantly reduces the uncertainty and subjectivity inherent in traditional visual inspections, providing critical, data-driven insights into structural conditions for quantitative, risk-informed infrastructure asset management.

Utilising advanced scanning and analysis software, the system leverages the magnetic properties of ferromagnetic materials to detect not only the extent and location of degradation and defects but also the distribution of stress within the structure. Since non-ferromagnetic materials like concrete do not interfere, the technology effectively identifies corrosion and cracking in reinforcement steel beneath the concrete surface and detects degradation in underground pipelines, as soil is also non-ferromagnetic.

This method is equally effective for detecting internal defects, such as flaws in railway tracks, and corrosion or pitting in pipes or plates beneath surface coverings like coatings or insulation. The equipment comprises a simple handheld scanner and datalogger, paired with sophisticated analysis software, making it a versatile and highly accurate solution for complex structural assessments.

ENERGY & UTILITY

In the Energy and Utility sector, non-invasive inspection technologies play a pivotal role in the continuous operation and maintenance of critical infrastructure. The patented iCAMM system enables precise detection of corrosion and structural anomalies in pipelines, underground utilities, and other essential assets, all without the need for service interruptions or insulation removal. This proactive approach enhances asset longevity, reduces maintenance expenditures, and ensures adherence to stringent safety and environmental regulations, safeguarding the uninterrupted provision of essential services.

AVIATION & AEROSPACE

Within the Aviation and Aerospace industries, maintaining structural integrity is paramount. Advanced inspection methodologies such as iCAMM offer unparalleled accuracy in detecting internal and external defects, including corrosion in high-stress steel components. This non-invasive technology supports rigorous safety protocols, minimising downtime while providing comprehensive data for informed maintenance decisions. By integrating this innovative solution, aerospace operators enhance airworthiness, operational efficiency, and safety compliance in highly regulated environments.

TRANSPORT

In the Transport sector, infrastructure such as railway tracks, bridges, and tunnels demands continuous monitoring to ensure safe and efficient operations. The iCAMM system, designed to detect internal flaws and corrosion in steel-reinforced structures, provides detailed corrosion mapping, enabling asset managers to prioritise interventions based on risk. This technology facilitates reduced service disruptions, cost-effective repairs, and extended asset lifespans, enhancing both public safety and transport reliability.

INFRASTRUCTURE & STRUCTURES

For critical infrastructure projects, timely and accurate assessment of structural integrity is essential. The iCAMM technology simplifies the detection of corrosion in steel reinforcements hidden beneath concrete, coatings, or other coverings, offering non-invasive, high-resolution scanning capabilities. This solution empowers asset managers with actionable data for risk-informed decision-making, allowing for strategic maintenance planning that reduces costs, enhances structural longevity, and promotes public safety in key infrastructure such as bridges, tunnels, and high-rise buildings.

MINING & RESOURCES

In the Mining and Resources sector, infrastructure is often exposed to harsh operational environments, accelerating the deterioration of key assets. The iCAMM system provides a non-invasive, non-destructive means of detecting corrosion in pipelines, conveyors, and structural supports, even in the presence of challenging conditions. This technology enables operators to conduct proactive inspections without disrupting production, increasing operational uptime, extending asset lifecycles, and mitigating the risk of costly, unplanned failures.

MARITIME & SHIPPING

The Maritime and Shipping sector faces unique challenges related to corrosion in marine environments. The iCAMM system offers a sophisticated solution for the detection of internal and external defects in vessels, offshore platforms, and port infrastructure, all while maintaining non-intrusive inspection protocols. By providing real-time, actionable data on structural health, this technology supports informed maintenance strategies that optimise asset reliability, reduce costs, and ensure compliance with maritime safety standards, even in the most demanding environments.